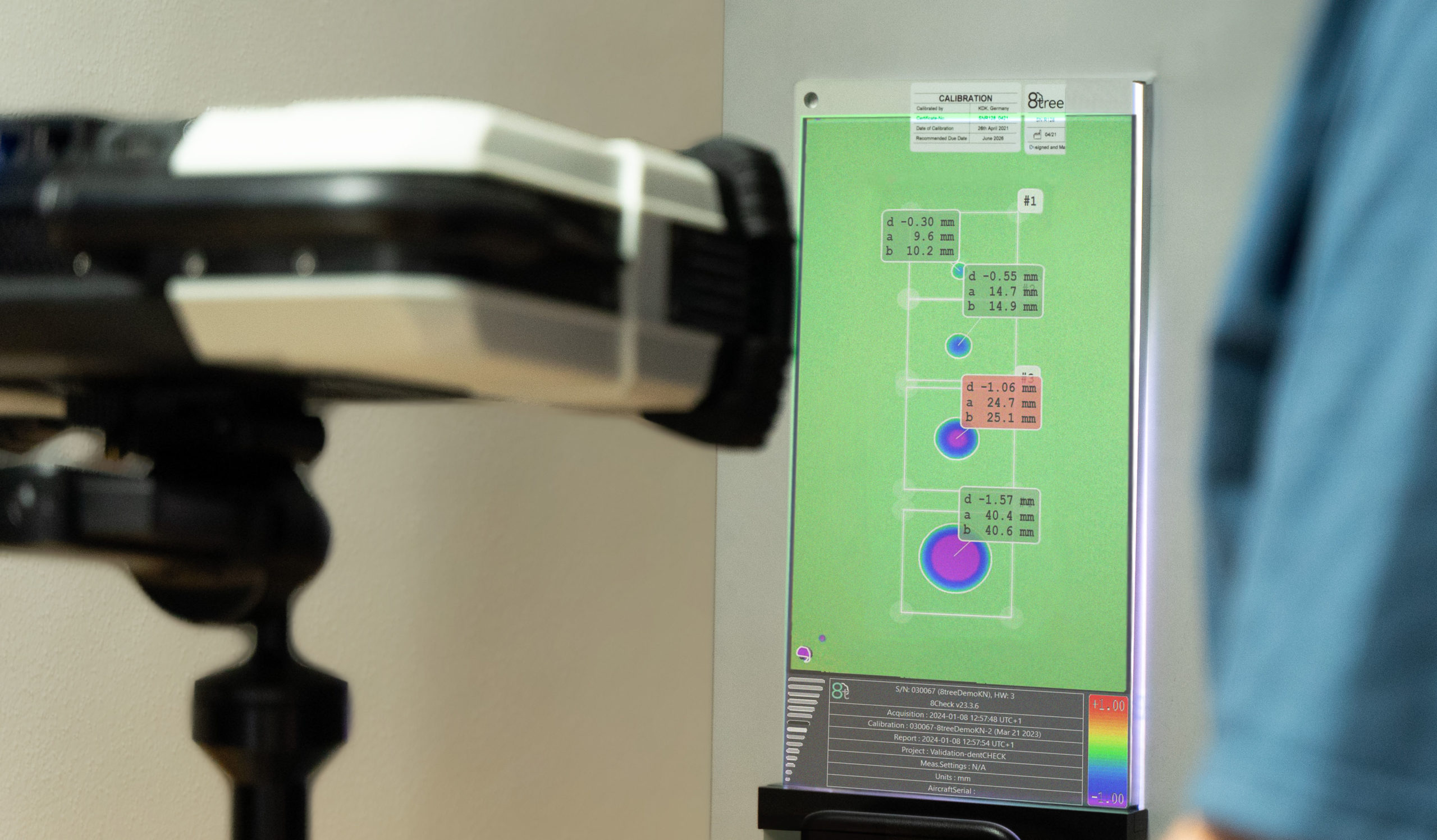

Accredited, proprietary calibration procedure based on highprecision machined reference standards

At 8tree, we specialize in measuring dents, bumps, and fastener flushness with unparalleled precision. Our measurement tools are the product of a unique, purpose-developed measurement principle that sets us apart in the industry.

Given the innovative nature of our technology, standard calibration procedures do not apply. Instead, we have meticulously crafted our proprietary calibration procedure through years of dedicated development.